A green company

ENO is an outdoorsy brand, and, as such, we’ve committed ourselves to sustainable development by promoting “Made in France” values.

Learn the secret to our exceptional longevity and our commitment.

Choosing a durable and robust plancha

From the design and manufacturing process to after-sales service, everything is done to ensure the longevity of our planchas. The labeling process has been implemented to justify this commitment to rewarding all the efforts made on a daily basis. Today, we are proud to have our entire range of planchas labeled LONGTIME®, a true testament of confidence for our customers.

LONGTIME®, the label for products designed to last. It provides you with the assurance that products bearing the label are reliable and repairable, breaking away from obsolescence. The label's specifications are the result of 2 years of consultation. It revolves around 3 pillars and includes 41 checkpoints for a comprehensive approach to sustainability: robust design, repairability, warranty, and after-sales service.

We guarantee all the products we manufacture because we know that prioritizing durability leads to consuming less energy, wasting less water, and generating fewer waste.

- Enameled cast iron is an indestructible material that does not scratch.

- Marine-grade stainless steel resists corrosion five times longer than brushed stainless steel.

- Hot-dip galvanized steel protects the steel under the paint, preventing oxidation in case of scratches.

- Polyester paint is seven times more resistant to UV rays than conventional epoxy

Our products are designed and tested to last and be repairable.

- Guaranteed products - certain spare parts are available for 20 years or more.

- Easy repair - the devices are fully dismantlable.

- Normative tests conducted in the laboratory.

- 100% checks on the production line (power, leaks, safety).

The steels are tested in a salt spray for 500 hours. They thus withstand the extreme conditions of outdoor use.

Full throttle for recycling

Whether it's cast iron, stainless steel, aluminum, brass, or copper, all these materials used in the composition of our planchas are 100% recyclable, and sometimes even made from already recycled materials.

Recycled materials for eco-friendly products

- Packaging and catalogs: manufactured and printed in France, using 70% recycled cardboard - Elimination of all plastics.

- Proportion of recycled material: steel/stainless steel (17.7%) - cast iron (33.5%).

- Systematic sorting of metal, plastic, and cardboard waste at each workstation.

- Automatic recycling of powders in the painting and enameling booths.

Recyclable products

- 100% of our products and their components are fully detachable and disassemblable: facilitating sorting

- 100% recycling and revaluation of production waste

- Contribution to recycling channels by joining ecosystem

- To better inform consumers, we indicate on all our packaging the sorting instructions using the TRIMAN logo

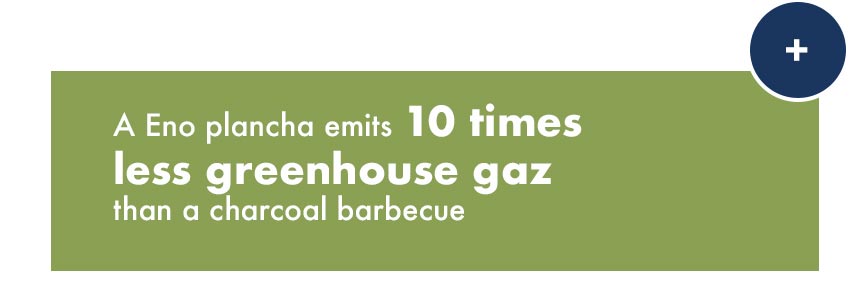

Zero carbon target ahead

With several initiatives in place to strive towards 'zero carbon', we also prove that eco-responsibility is certainly not just an empty phrase for us..

- Investment in a fleet of modern and energy-efficient machines.

- Use of clean application techniques, solvent-free, water-free, and in closed-loop systems, for enameling and painting.

- Recovery of heat from certain ovens to heat workshops through cogeneration.

- Transition to Factory 4.0: digitalization and robotization reduce labor intensity, transition to "paperless" operations, and optimize flows.

- Preference for short supply chains in sourcing and supplier selection.

- Reduction of water consumption by 23%, gas consumption by 40% in the enameling process.

- Systematic water treatment in our wastewater treatment plant (60 control points before discharge)

Energy is precious

Each plancha receives the burner best suited to its size, plate thickness, and chassis shape to optimize consumption.

- High-performance burners and fireplaces: 25% energy consumption reduction compared to products on the market.

- Double-walled chassis for optimal flame confinement: no energy loss.

- Thick cast iron plate (7 mm) with double walls to retain heat; cast iron is the material that retains heat best.

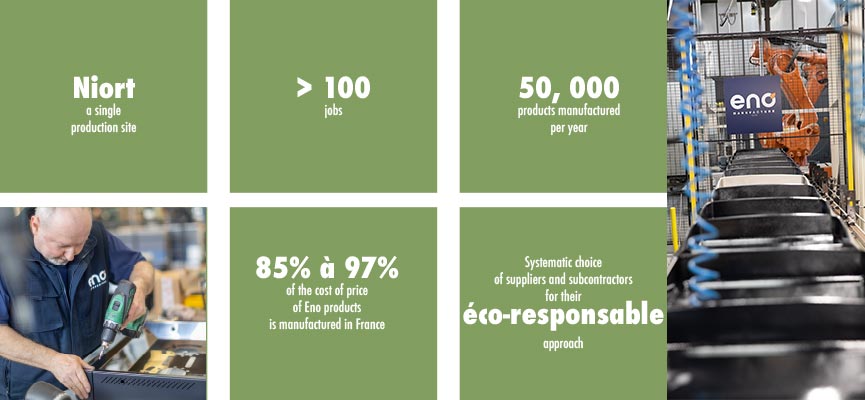

Proud to manufacture in France since 1909

Made in France certified since 2011

As the first French manufacturer to obtain the Made in France label, our century-old company proudly demonstrates its steadfast commitment to prioritizing the local ecosystem. This certification authenticates the French origin of our products and showcases our industrial commitment for over 10 years.

Eno, honored at the Élysée Palace

Featured at the 'Great Exhibition of Made in France' in January 2020, the new Enosign plancha was selected among the 101 French products invited to represent French know-how.